In the realm of technological advancements, automation stands as a cornerstone concept that has profoundly transformed industries and businesses. While often used interchangeably, Industrial Automation (IA) and Robotic Process Automation (RPA) are distinct areas of automation with specific applications, benefits, and technologies. Understanding the differences and how they can complement each other is crucial for businesses looking to optimize their operations. This article explores these two forms of automation, highlighting their unique features and discussing the role of technologies like servo motors in enhancing their effectiveness.

What is Industrial Automation?

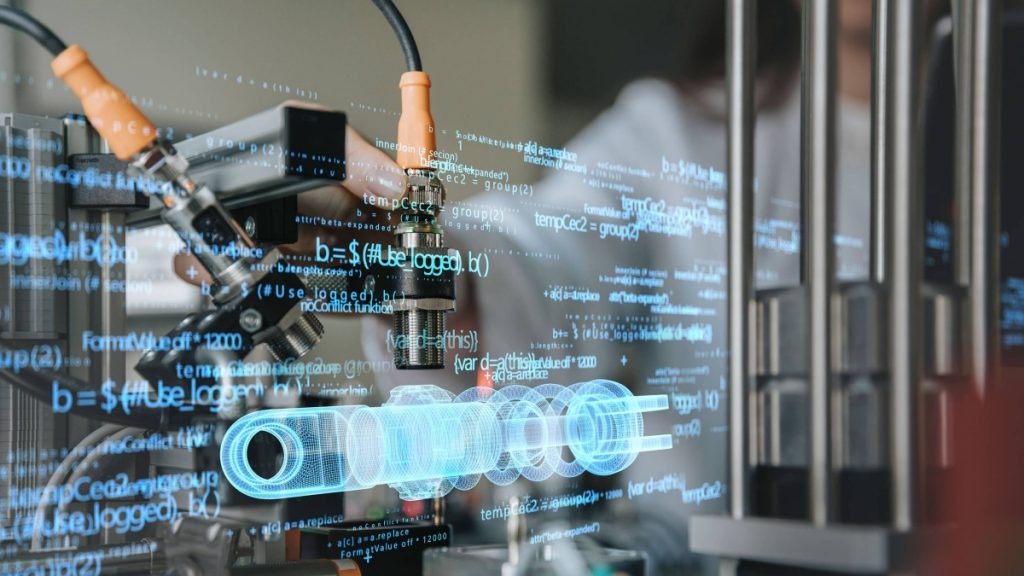

Industrial automation encompasses the use of control systems—such as computers, robots, and information technologies—to manage various processes and machinery within an industry, enabling the production of goods or services with minimal human intervention. Its main focus is to enhance the efficiency, reliability, and speed of industrial operations. Key components of this automation include PLCs (Programmable Logic Controllers), sensors, and actuators like servo motors, which provide precise control over machinery involved in manufacturing processes.

Servo motors, in particular, are essential in industrial automation due to their ability to provide precise movement control, crucial for tasks that require high accuracy such as in assembly lines or robotic arms. These motors can adjust the speed, position, and torque of the machines they control, directly impacting production efficiency and product quality.

What is Robotic Process Automation?

Robotic Process Automation (RPA) is a technology that enables users to configure software, or “robots,” to mimic human actions within digital systems and execute business processes. RPA robots interact with user interfaces to capture data and manipulate applications just as humans do. They interpret information, trigger responses, and communicate with other systems to perform a wide range of repetitive tasks. Unlike traditional IT solutions, RPA empowers organizations to automate processes more efficiently, saving both time and costs.

RPA is primarily used to automate routine office tasks—typically clerical and rule-based tasks that require little human judgment. These tasks include queries, calculations, maintenance of records and transactions, which can span across multiple IT systems.

Comparing Industrial Automation and Robotic Process Automation

Application Areas: The fundamental difference lies in their application areas. Industrial Automation is predominantly used in manufacturing sectors such as automotive, electronics, and food processing, where there is a need to control physical operations and machinery. RPA, however, is mostly applied in sectors like banking, insurance, and healthcare for data entry, form processing, transaction processing, and compliance reporting.

Technology Utilization: Industrial Automation makes extensive use of physical robotic arms, conveyors, and assembly lines integrated with sophisticated feedback systems like those provided by servo motors like the MMD042A-030-EG0-CN. RPA, conversely, involves software robots that simulate human actions on a graphical user interface (GUI) level, requiring no physical interaction with the process they automate.

Complexity and Scalability: Industrial Automation deals with complex machinery and requires significant initial investment in terms of capital, planning, and configuration. Its scalability often involves further substantial investments in hardware. RPA is relatively easy and quick to implement and can be scaled up or down with minimal costs compared to industrial automation.

Integration and Flexibility: IA often requires significant changes to accommodate new production lines or processes due to its dependence on physical infrastructure. RPA is highly flexible, allowing for rapid adjustment to business processes and easy integration with existing IT environments without the need to overhaul existing systems.

Synergies Between IA and RPA

Despite their differences, IA and RPA can complement each other to enhance business processes. For instance, RPA can handle data management tasks required in industrial automation settings, such as scheduling operations, managing inventory data, or processing orders, which feeds into the physical processes handled by IA. This integration can lead to a more seamless flow of operations, reducing bottlenecks and improving overall efficiency.

Conclusion

Understanding the distinctions between Industrial Automation and Robotic Process Automation is crucial for any business looking to invest in automation technologies. While each has its specific uses, the two can complement each other to provide comprehensive automation solutions that leverage both physical and software-based technologies. Servo motors and other advanced components continue to play a crucial role in enhancing the precision and efficiency of these automated systems, underscoring the importance of integrating suitable technologies according to specific industrial needs. As the landscape of automation continues to evolve, the strategic application of IA and RPA will be critical in driving the next wave of productivity enhancements in various industries.