Marking on items is probably one of the oldest hobbies with human as researches showed our ancestors placed different markings and engravings on rocks and bones half a million years ago. This interest has been kept to the modern era, and laser marking becomes a vital aspect of a business.

A start for marking machines in the business area

In 1973, the first Pneumatic marking device was developed in the U.S. With over 30 years of progress in refining this technology, China produced the first single-chip microcomputer based Pneumatic marking machine.

Although Pneumatic marking is the old technology, it opened up the marking machine industry and allowed people to realise the importance and essential application of marking to a business.Then it comes to the laser marking era.

Laser marking machines advance to be the essential

The history of laser marking began with marking and engraving on metal (Laser wavelength 1064nm). The first generation was a lamp pumped YAG laser marking machine. With its low energy transfer efficiency and huge size, it was weeded out by the diode-pumped laser marking technique. Its compactness and efficiency became the most significant advantages over the previous generation and could be used in many other scientific applications that made it a favourable option for many industries.

However, people never stop in inventing better solutions, which led to the appearance of the fiber laser sourced marking machine. Its precision, higher cost performance ratio than UV marking, and extensive application on sophisticated parts such as auto parts and 3C electronic products and components, resulted in most industries apply this technology for marking and personalization. Non-metal products and items (Laser wavelength 10640nm) also desired to utilize the laser marking technology; therefore, CO2 laser marking machines are specially designed for non-metal and produced by some leading companies such as TASTELASER to meet various industry demands nowadays.

Why businesses need laser marking machine

After introducing the brief history of marking machines development, we realise the marking industry has been advancing with the enterprises and becoming one of the essential parts for companies, especially those in industrial and manufacturing areas. All business sectors can often realise benefits for laser marking; let’s see what they are:

- Quality of marking and engraving

Quality is one the biggest of advantages over other marking approaches. The laser beam is much smaller than physical engraving, and each machine is computer controlled, and therefore precision is increased tremendously.

It allows the creations of complex forms, making small figures and text more readable, as well as each marking, can be done seamlessly.

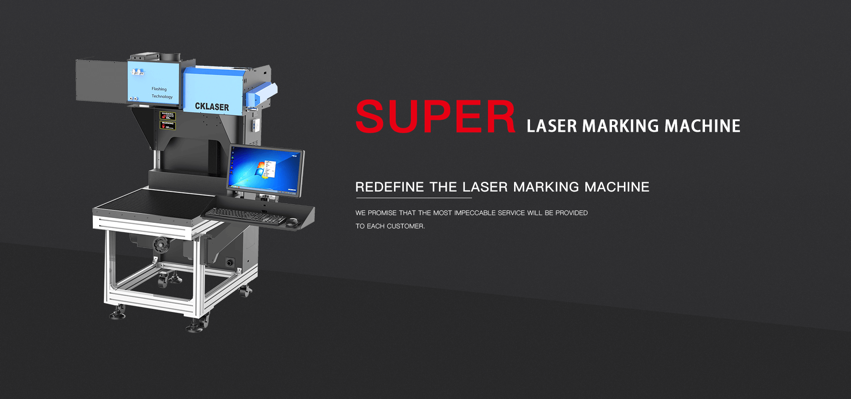

Recently, TASTELASER introduced their Super Power CO2 Laser Marking Machine with an adsorptive platform and advanced exhausting system. These features allow the objects close to the working plane and prevent position deviation, meanwhile absorb dust and smoke to ensure the stability during the marking process.

- Introduce Uniqueness to your products

Every business should aim to stand out from its competitors and distinguish itself from other products to increase sales and promote better brand recall and loyalty. Laser marking enables enterprises to perform better in this aspect.

For 3C component and auto parts, have the business name and its logo on the items can help users trace the origins and they can come back to you and reorder products. For non-metal materials that are usually done by CO2 laser marking, the machine provides the ability to engrave unique text, graphics and bar code to differentiate your products from the others. Personalisation can become a critical feature for businesses. For instance, Lamy offers customers to engrave their logo or names on the pen and corporates are willing to pay extra money to enable stronger differentiation.

- Fast process without sacrificing durability

The ability to penetrate and engrave is another huge selling point of laser marking machines. It shortens the process of marking, which not just save time but also cutting costs in manufacturing. Further, the quality and durability are not lost as laser marking is permanent as long as the material’s surface is not heavily damaged.

Practical innovations in CO2 laser marking

TASTELASER is an excellent example of a company continually innovating in laser marking and provide reliable business solutions. For instance, in their Super Power CO2 Laser Marking Machine model, they are not only introducing adsorptive platform and advanced exhausting system, but also dynamic focusing large-span technology, world exclusive power control card and many more. These advancements expand the possibility of laser marking and provide more opportunities for its clients to increase their performance in respective areas.