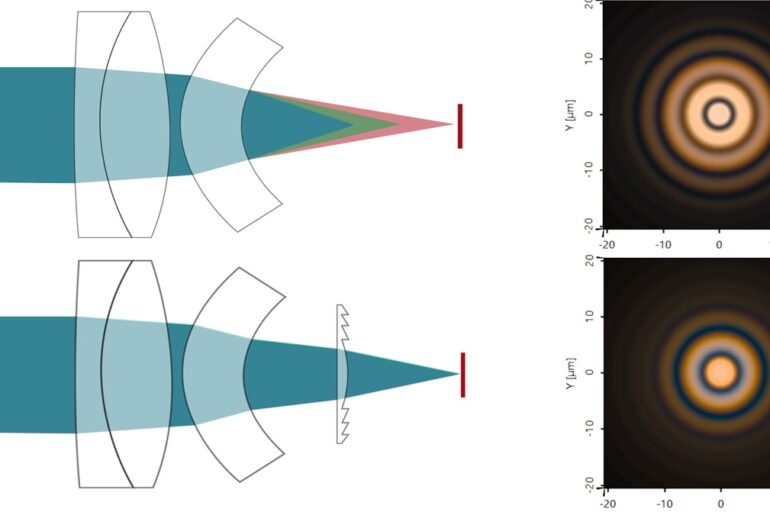

A conventional refractive optical lens works according to the laws of refraction that dictate that a beam of light will alter its trajectory when going from air to a denser media like water or glass. Based on this principle, a piece of glass with a predefined curvature can focus a light beam. A diffractive optical lens, on the other hand, will instead make use of the principle of diffraction which is based on the wave nature of light. Diffractive optical lenses are also known as Fresnel zone plates although a diffractive lens can be considered to be a more general type of optical component.

The advantage of a diffractive optical lens when compared to a conventional lens is that the former can be more compact and lightweight, which makes it an attractive solution for micro-optical systems. They are better poised for high laser power applications as the coating for laser damage control has to operate only at normal incidence.

To design a diffractive optical lens of a certain focal length one starts by calculating the curvature profile of an equivalent conventional optical lens. This curvature profile is then modulated to a height of a single wavelength and sampled along the spatial directions, then the curvature is approximated with discrete phase steps. Those discrete phase steps can be embossed on a glass or plastic substrate, which is the normal manufacturing process for all diffractive optical elements. This will result in a thin and lightweight optical element that is capable of focusing a beam of light and forming images. Their manufacturing process also renders them less sensitive to focal length changes with varying temperature. Moreover, given that the design process starts with an analytical profile, there are basically no constraints in the shape of the curvature profile so any aspheric or conic profile can be encoded without concern about the manufacturability of those lens profiles.

Diffractive optical lenses can be used in those applications that are weight sensitive and when miniaturisation is paramount. Among some applications we can cite the following.

- Beam collimation in fiber optics arrays.

- Structured light applications that involved laser diode arrays or VCSELs.

- Athermal lenses for high power applications.

The spectral dispersion arising from diffractive effects is higher than the dispersion coming from refractive effects. But on the other hand, the dispersion from these two effects are reversed from one another. Considering this fact, the overall dispersion on an optical system can be balanced by using a combination of diffractive and conventional lenses.